How Insulated Glass Works

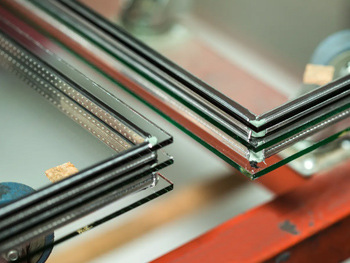

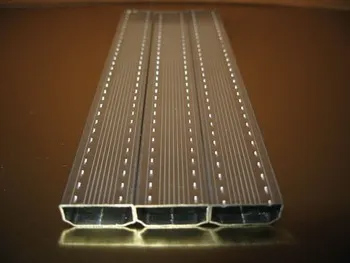

Insulated glass units, often called IGUs, are engineered to deliver exceptional comfort and efficiency. These windows are crafted with two or more panes of glass that are carefully separated by a spacer, creating an insulating chamber between them. Think of it as a built-in thermal shield, working quietly to stabilize interior temperatures year-round.

The real insulating power lies in the space between the panes. While some systems use ordinary air, most high-performance IGUs are filled with specialized gases such as argon or krypton. These gases significantly slow the transfer of heat, helping to keep warmth indoors during winter and unwanted heat outdoors in summer.

To maintain clarity and longevity, the spacer is packed with a desiccant — a moisture-absorbing compound that prevents condensation and humidity from forming between the panes. This detail is critical to ensuring the glass stays clear and effective for years to come.

Production involves a precise, multi-step process. Each pane is paired with its spacer, sealed within a controlled environment, and infused with insulating gas. Once assembled, the unit undergoes polishing and a final application of durable sealants around the perimeter. This airtight seal ensures that gas stays in, moisture stays out, and the unit performs to its highest potential.

At US GLASS TEMP, this meticulous process is elevated into an art form — combining advanced engineering with uncompromising quality to deliver glass solutions that are as functional as they are beautifully crafted

Insulated Glass Components

Polyisobutylene (PIB) forms the first line of defense in every insulated unit. This high-performance sealant minimizes the passage of moisture while delivering one of the industry’s lowest rates of argon loss. The result is reliable insulation that preserves energy efficiency over time.